DAVID LLOYD ENFIELD

CASE STUDY

.

David Lloyd, one of the leading health and fitness club operators in the UK, aimed to enhance the operational efficiency of their Enfield fitness centre's kitchen. Recognising the need to reduce energy consumption, David Lloyd partnered with Intelli-Hood to install its Demand Control Kitchen Ventilation (DCKV) system. Intelli-Hood's smart technology utilises dual sensing to monitor real-time cooking activity and modulates commercial kitchen fan speeds to optimise energy usage and improve overall kitchen performance.

Overview

The installation of Intelli-Hood's advanced DCKV system was meticulously planned and executed to minimize disruption to staff, customers, and daily operations. The project team worked closely with David Lloyd’s facility to schedule the installation during off-peak hours, ensuring the fitness centre's kitchen could continue serving its patrons without interruptions. The process involved integrating Intelli-Hood's dual sensing technology into the existing ventilation system and configuring the controls to accurately monitor and adjust fan speeds based on cooking demand. As a result, the project was completed efficiently with no reported delays or operational setbacks.

Implementation

Annual Kitchen Canopy Utility Costs (GBP)

Figure A

Figure A portrays the annual utility costs before & after Intelli-Hood’s DCKV system was installed at the fitness centre. The graph shows the savings achieved with Intelli-Hood after installation.

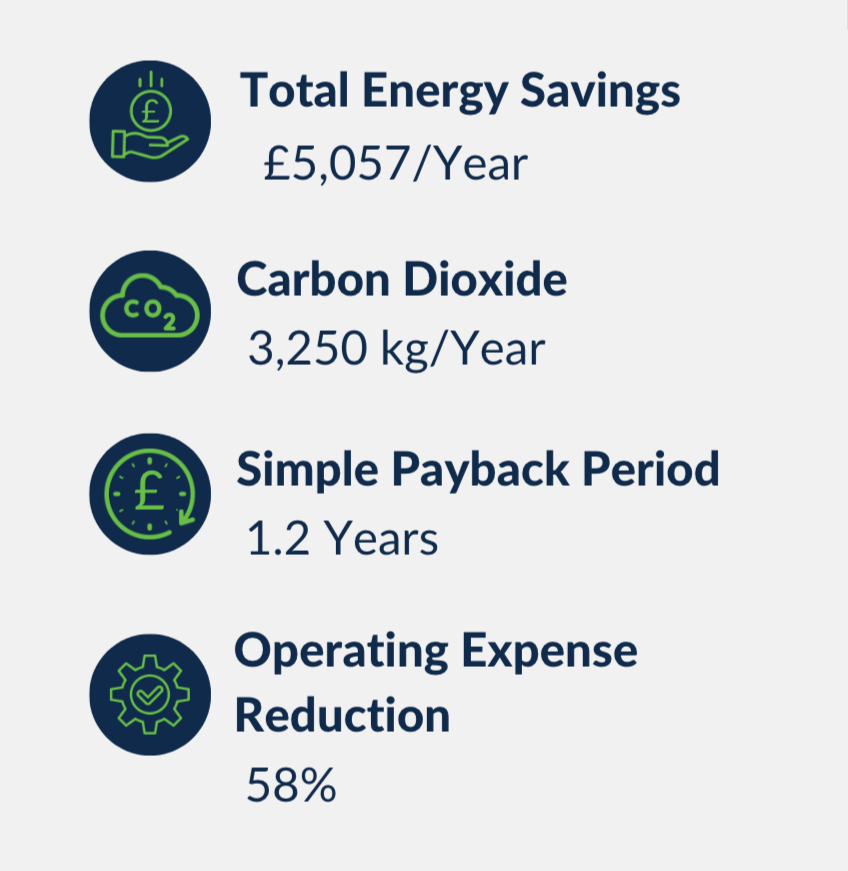

The installation of Intelli-Hood's DCKV system delivered significant improvements in energy efficiency and operational cost reduction. Prior to installation, the David Lloyd fitness centre’s annual utility costs were approximately £9,506. Following the deployment of Intelli-Hood, these costs were reduced to £4,448, representing an annual savings of £5,057. This impressive reduction in energy expenditure equates to a 58% decrease in operating expenses.

A key contributor to these savings was the system's ability to modulate kitchen fan speeds effectively. Before installation, the fans were running at an average speed of 100%, leading to significant energy waste. With Intelli-Hood, fan speeds were optimised to an average of 61%, aligning closely with real-time cooking demand. This reduction not only improved energy efficiency but also helped extend the lifespan of the kitchen ventilation system.

In addition to cost savings, the installation of Intelli-Hood contributed to David Lloyd's sustainability goals. By reducing energy consumption, the fitness center significantly lowered its overall carbon emissions, resulting in a savings of 3,250 kg per year. This reinforces their commitment to environmental responsibility.

Project Recap

David Lloyd - Average Fan Speed

Figure B

Figure B depicts the fan speed variations over the course of five days. The variations in fan speed are a result of changing cooking demand in the commercial kitchen. Average Fan speed was 61%.

The installation of Intelli-Hood's smart DCKV technology at David Lloyd's fitness centre in Enfield exemplifies how advanced energy-saving solutions can deliver measurable financial and environmental benefits. By reducing utility costs by 58% and optimising fan speeds to eliminate energy waste, the fitness centre achieved annual savings of £3,280. Furthermore, the project was executed seamlessly, with minimal disruption to staff and daily operations. The success of this project highlights the value of adopting intelligent energy solutions in commercial kitchens to improve efficiency, reduce operating expenses, and promote sustainability.