IKEA RETAIL CASE STUDY

.

The IKEA retailer in Reims, France, faced operational challenges with its existing kitchen controls, resulting in dissatisfaction with performance. Seeking improved efficiency and sustainability, IKEA opted to retrofit Intelli-Hood®'s Demand Control Kitchen Ventilation (DCKV) controls to monitor and optimise their kitchen's performance.

Overview

To ensure minimal disruption to staff, customers, and daily operations, the installation process was meticulously planned and executed. The retrofit took place outside of peak hours of operation, with careful coordination to avoid disruptions, including thorough communication with staff to manage expectations. By optimising the installation schedule and employing efficient techniques, IKEA maintained seamless operations while upgrading their kitchen controls, demonstrating their commitment to customer satisfaction and operational excellence.

Implementation

Annual Kitchen Canopy Utility Costs (GBP)

Figure A

Figure A compares the annual utility costs prior to Intelli-Hood®’s installation vs. after. The graph highlights the savings achieved by IKEA as a result of Intelli-Hood®’s DCKV installation.

Disclaimer: This installation was conducted by a local distributing partner of Intelli-Hood. For any questions or more info regarding this installation, please contact the Melink Corporation.

Prior to the installation of Intelli-Hood®, the kitchen operated with a different type of controls, leading to inefficiencies and high utility costs. The annual utility expenditure amounted to £25,107, posing a significant financial burden and environmental impact. IKEA recognised the need for a solution that not only optimised energy usage but also aligned with their commitment to sustainability.

Following the installation of Intelli-Hood®, remarkable improvements were observed in the kitchen's performance and utility costs. The annual utility cost plummeted to £9,195, resulting in a substantial annual savings of £15,912. This remarkable reduction translated to a 63% decrease in operating expenses, demonstrating the tangible benefits of Intelli-Hood®'s DCKV controls.

Intelli-Hood®'s DCKV controls proved instrumental in optimising the kitchen's energy usage. The average fan speed of 45% ensured that ventilation was aligned with cooking demand, reducing energy wastage significantly. This not only enhanced operational efficiency but also contributed to the IKEA retailer's sustainability goals.

Performance Results

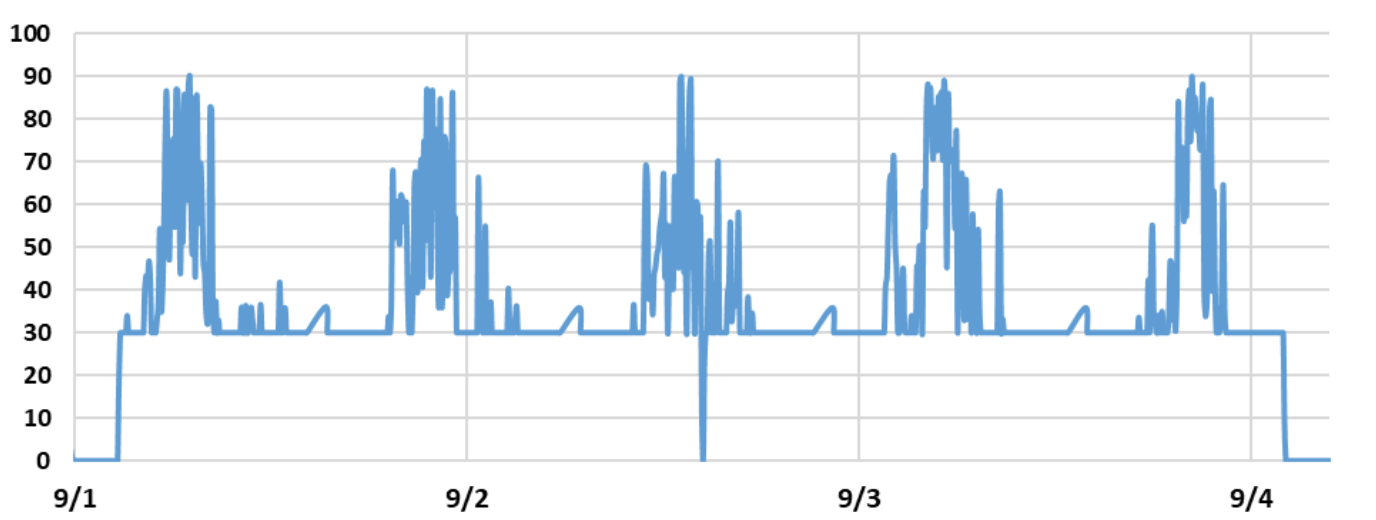

IKEA Reims France - Average Fan Speed

Figure B

Figure B depicts the retailer’s commercial fan speed profile over the course of four days. The average was 45%. The spikes in the fan speed represent the increase of cooking demand and the dips represent the decrease of cooking demand.

In addition to energy efficiency, Intelli-Hood® helped the IKEA retailer in Reims become more sustainable. The kitchen achieved an impressive annual CO2 savings of 45,793 kg/year, mitigating its environmental footprint and aligning with IKEA's commitment to environmental stewardship.

Environmental Impact

IKEA Cafeteria Kitchen

The retrofit installation of Intelli-Hood®'s DCKV controls at the IKEA retailer in Reims, France, yielded substantial benefits in terms of efficiency, cost savings, and sustainability. With a simple payback period of 1.9 years, the investment proved to be economically viable. By reducing operating expenses, optimising energy usage, and minimising environmental impact, Intelli-Hood® empowered IKEA to enhance its kitchen operations while advancing its sustainability agenda. This case study underscores the transformative impact of Intelli-Hood® in commercial kitchens, exemplifying its role as a catalyst for efficiency and sustainability in the foodservice industry.

Conclusion