MCDONALD’S MULTISITE CASE STUDY

.

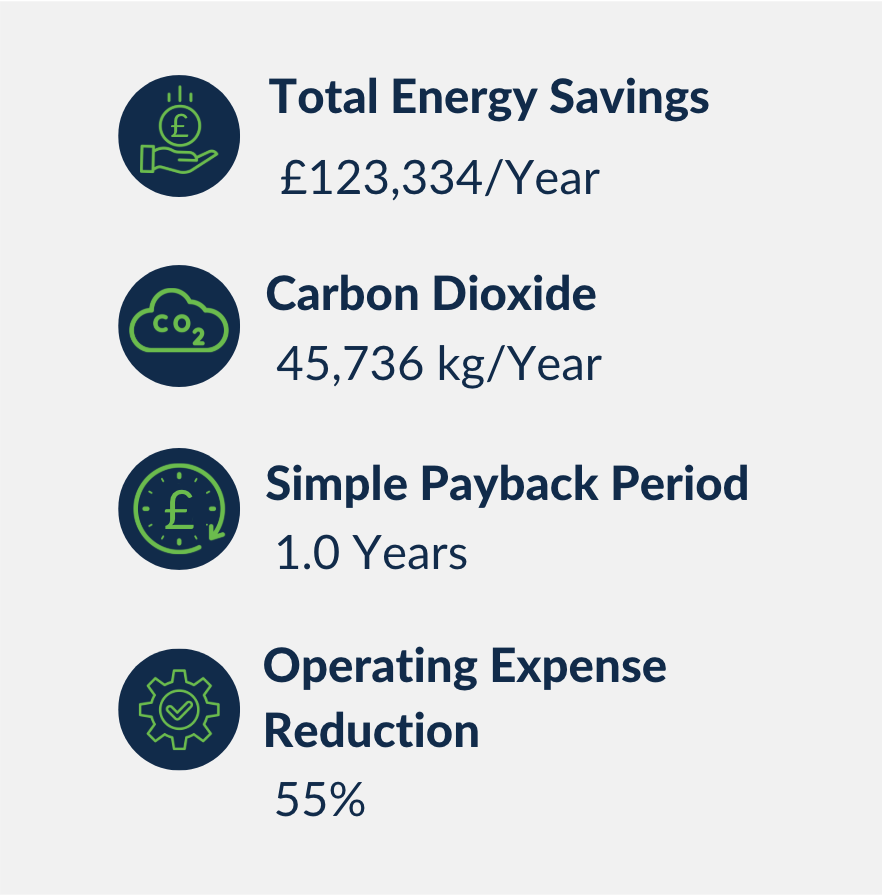

This muti-case study shows the performance results for 40+ McDonald's locations. McDonald's is a fast-food restaurant chain and the number one restaurant chain in the world. The study shows how an Intelli-Hood® installation was able to reduce the facility's annual utility costs and carbon dioxide emissions. With the rise of utility rates across multiple locations, Intelli-Hood® was the proactive strategy for McDonald's to offset increased energy costs with efficiency upgrades.

Overview

Benefits

In the chart below, Figure A, the average fan speed for the exhaust fans is shown over the course of two weeks. The dips in the chart represent times when the fans have slowed down due to reduced cooking intensity. While the spikes represent when the fans are operating at a greater cooking intensity and higher heat loads. The varying fan speed means the fans are running more efficiently rather that consistently at full speed. The average fan speed for these exhausts was 68%.

McDonald’s Sample Site - Fan Speed

Figure A

Annual Kitchen Canopy Utility Costs (GBP)

Figure B

Figure B depicts the customer's annual energy costs as compared to their net energy costs. After installing Intelli-Hood®, these locations operated at £168,463 on average for their utility costs. That's a £123,334 annual savings across these locations, as compared to their previous operating utility costs.

Disclaimer: This installation was conducted by a local distributing partner of Intelli-Hood. For any questions or more info regarding this installation, please contact the Melink Corporation.